What should we Expect of 3D Printers in the Near Future?

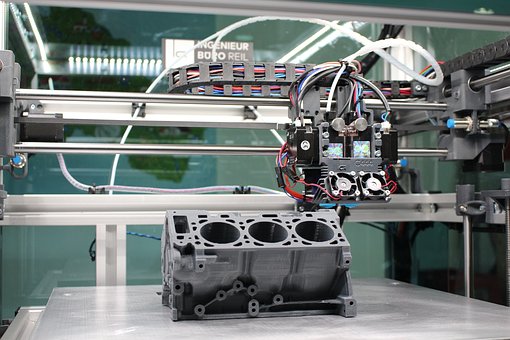

The use of 3D printing continues to soar as more and more people turn to this technology as a cost-effective way of prototyping. This technology has seen a rise of businesses trying to tap on the benefits of his technology.

Though 3D printing technique was initially used in the manufacture of items out of plastic, new materials such as metals &composites of carbon fiber and wood are in use.

One of the big wins for 3D technology is you don’t require to make or purchase and special tools or molds. The technology is and will remain to revolutionize the entire industrial landscape. A 3D printer based company can customize products based on the client’s requirements.

Let us look at the trends we expect to see in this year and beyond in 3 D technology.

As you might know, innovation in this vibrant industry happens at unimaginable speeds. In the near future we should expect the following:

Mass Production of Goods

3D printing technology will result in many changes in industrial processes. For instance, companies that adopt extensive use of 3 D printing can enjoy customized mass production. This means that it is possible to get a company producing a pair of ski boots or sneakers of the same quality and fit in large numbers using this technology.

Increased Returns

Industrial users of 3D technology should expect better returns since the prosumer market for 3D printers is heating up. The reason is, the market is likely to see an increase of high end ($1000) 3d printers to create specialty products. This means the technology, including the printing machines, will be cheaper.

Use of Friendly Materials In the Manufacturing Process

We are likely to see more and more materials used in the manufacture of different products using 3 D technology. More biocompatible materials will get into use. Materials such as metals, e.g., tungsten carbide and aluminum that are faster and easy to print using this technology may get wider recognition.

Increased Automation

The level of automation and integration of 3 D printing systems is expected to increase. For example, a 3D printing company will require fewer employees to run the system due to increased automation.

Efficient Utilization of Raw Materials

At present, 3D technique printing experiences lots of wastes but this is likely to change as the software gest better besides more exacting. We can expect 3D systems that can recycle wastes, thus less wastage. We can, therefore, say that in the near future, 3D technology will become cheaper and efficient.

…